Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

Duplex stainless steel tubing and pipes, either seamless or welded, are intended for services requiring general corrosion resistance, with particular emphasis on resistance to stress corrosion cracking. There are several prevalent duplex grades that can be readily sourced from most pipe mills: UNS S31803, UNS S32205, UNS S32750 and UNS S32760. Both S31803 and S32205 are designated as alloy 2205, while S32750 are designated as alloy 2507.

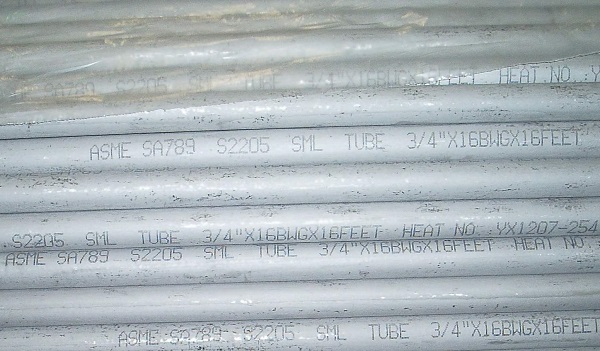

ASTM A789/ ASME SA-789 UNS S32205 (alloy 2205) seamless tubing; O.D. = 3/4″, W.T. = 16 BWG (0.065″), L = 16 feet; supplied for the construction of an evaporator of a desalination system; Dubai, UAE.

Duplex stainless steel tubing or tube, either seamless or welded, shall be manufactured in according with ASTM A789 (ASME SA-789), which is a hollow product of round or any other cross section having a continuous periphery. The tubing is produced to the actual outside diameter and minimum or average wall thickness specified by the purchaser. The wall thickness of tubing is normally given in decimal parts of an inch rather than as a fraction. When gauge numbers are given without reference to a system, Birmingham Wire Gauge (BWG) is implied.

| Gauge No. | B.W.G. inch |

|---|---|

| 0000 | 0.454 |

| 000 | 0.425 |

| 00 | 0.380 |

| 0 | 0.340 |

| 1 | 0.300 |

| 2 | 0.284 |

| 3 | 0.259 |

| 4 | 0.238 |

| 5 | 0.220 |

| 6 | 0.203 |

| 7 | 0.180 |

| 8 | 0.165 |

| 9 | 0.148 |

| 10 | 0.134 |

| 11 | 0.120 |

| 12 | 0.109 |

| 13 | 0.095 |

| 14 | 0.083 |

| 15 | 0.072 |

| 16 | 0.065 |

| 17 | 0.058 |

| 18 | 0.049 |

| 19 | 0.042 |

| 20 | 0.035 |

| 21 | 0.032 |

| 22 | 0.028 |

| 23 | 0.025 |

| 24 | 0.022 |

| 25 | 0.020 |

| 26 | 0.018 |

| 27 | 0.016 |

| 28 | 0.014 |

| 29 | 0.013 |

| 30 | 0.012 |

| 31 | 0.010 |

| 32 | 0.009 |

| 33 | 0.008 |

| 34 | 0.007 |

| 35 | 0.005 |

| 36 | 0.004 |

Duplex alloy 2507 seamless pipes made of ASTM A790 Gr. S32750; 10″ SCH40 (273.0 mm x 9.27 mm) L=5250 mm; Delivered to Port of Basrah, Iraq.

Duplex stainless steel pipe, either seamless or straight-seam welded, shall be manufactured in accordance with ASTM A790 (ASME SA-790), which is a tube with a round cross section conforming to the dimensional requirements for nominal pipe size & schedule number as tabulated in ASME B36.10M and ASME B36.19M. For custom-designed special DSS pipe have diameter not listed in the above mentioned standards, the nominal diameter corresponds to the outside diameter and the actual wall thickness shall be specified.

| EL. | S31803 | S32205 | S32750 | S32760 |

|---|---|---|---|---|

| C | ≤0.030 | ≤0.030 | ≤0.030 | ≤0.030 |

| Mn | ≤2.00 | ≤2.00 | ≤1.20 | ≤1.00 |

| P | ≤0.030 | ≤0.030 | ≤0.035 | ≤0.030 |

| S | ≤0.020 | ≤0.020 | ≤0.020 | ≤0.010 |

| Si | ≤1.00 | ≤1.00 | ≤0.80 | ≤1.00 |

| Ni | 4.5-6.5 | 4.5-6.5 | 6.0-8.0 | 6.0-8.0 |

| Cr | 21.0-23.0 | 22.0-23.0 | 24.0-26.0 | 24.0-26.0 |

| Mo | 2.5-3.5 | 3.0-3.5 | 3.0-5.0 | 3.0-4.0 |

| N | 0.08-0.20 | 0.14-0.20 | 0.24-0.32 | 0.20-0.30 |

| Cu | - | - | ≤0.50 | 0.50-1.00 |

| W | - | - | - | 0.50-1.00 |

| Test | S31803 | S32205 | S32750 | S32760 |

|---|---|---|---|---|

| Su | 620 [80] | 655 [95] | 800 [116] | 750 [109] |

| Sy | 450 [65] | 485 [70] | 550 [80] | 550 [80] |

| El. | 25 | 25 | 15 | 25 |

| HBW | 290 | 290 | 300 | 310 |

| HRC | 30 | 30 | 32 | 32 |

| HV | 390 | 290 | 300 | 310 |

The eddy current test for a duplex stainless steel pipe (alloy 2507) made in accordance with ASTM A790.

According to ASTM A789 or ASTM A790, the seamless duplex stainless steel tubing or pipe shall be made by a seamless hot-rolled or cold-drawn process. The welded duplex stainless steel tubing or pipe shall be made by an automatic welding process, with no addition of filler metal in the welding operation. All DSS tubes made to ASTM A789 and all DSS pipes made to ASTM A790 shall be furnished with the solution annealing treatment followed by a water quench. The solution annealing temperature ranges for S31803, S32205, S32750, and S32760 are 1870-2010°F [1020-1100°C], 1870-2010°F [1020-1100°C], 1880-2060°F [1025-1125°C], 1960-2085°F [1070-1140°F], respectively.

Packaging of DSS tubes (ASTM A789 Gr. S32205), to be delivered to Santiago, Chile.

The ASTM A789 DSS tubing and ASTM A790 DSS pipe can be used for heat exhangers in refineries, chemical industries, process industries, and other industries using water as a coolant. They can be used for the connection of chemical tanks, chemical reactor vessels, flue gas filters, acetic and phosphoric acid handling systems, oil & gas flow lines, pulp and paper piping systems, food and brewery process piping, etc. Pipes and tubes made from super duplex grades S32750 and S32760 can be used for seawater desalination systems, oil and gas separators, salt evaporation piping, and geothermal well heat exchanging systems.