Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

Flat-rolled products made from typical austenitic stainless steels ASTM A240 Types 304/304L and 316/316L can be classified as plates, sheets and strips. The UNS designation numbers of Type 304, 304L, 316, 316L are S30400, S30403, S31600, S31603, respectively. Type 304 stainless steel has the classic 18Cr-8Ni nominal composition, which is the most common steel for corrosion resistance. Type 316 (nominal composition of 16Cr-12Ni-2Mo) is the modified version of Type 304 with addition of molybdenum, which exhibits superior resistance to pitting corrosion in chloride environments. Types 304L and 316L are the low carbon versions of Type 304 and 316 respectively. The low carbon addition improves the steel’s welding performance as well as corrosion resistance.

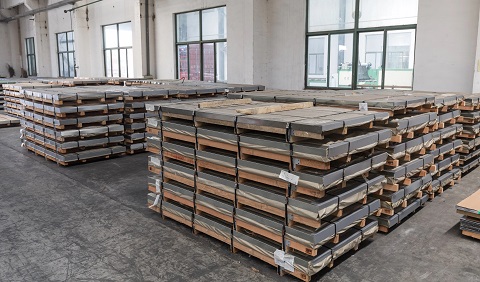

Various stainless steel plates made from ASTM A240 type 304, in a warehouse in Wuxi, Zhejiang Province.

According to ASTM A480, a plate is the flat-rolled product 3/16″ [5 mm] and over in thickness and over 10″ [250 mm] in width. A sheet is the flat-rolled product under 3/16″ [5 mm] in thickness and 24″ [600 mm] and over in width. A strip is the cold-rolled flat product under 3/16″ [5 mm] in thickness and under 24″ [600 mm] in width. The ASTM A240 304/304L and 316/316L stainless steel plates, sheets and strips widely used for the construction of pressure vessels and for general applications including architectural, building, construction, and aesthetic applications.

The starting material (often the slabs or ingots) of the flat-rolled stainless steel product shall be made by an electric-arc or electric-induction melting or remelting process. Plate is usually produced by hot rolling from slabs that have been directly cast or rolled from ingots and that usually have been conditioned to improve plate surface. Some plates may be produced by direct rolling from ingot. ASTM A240 304/304L and 316/316L plates are generally produced in the annealed condition and is either blast cleaned or pickled. Plate can be produced with mill edge and uncropped ends. This plate is referred to as sheared plate or sheared mill plate when rolled between horizontal rolls and trimmed on all edges, and as universal plate or universal mill plate when rolled between horizontal and vertical rolls and trimmed only on the ends.

ASTM A240 type 316L stainless steel sheets, packaged in plywood pallets, supplied to Manzanillo, Mexico.

Stainless steel sheets made of ASTM A240 304/304L & 316/316L are almost exclusively produced on continuous mills. The steel is cast in ingots, and the ingots are rolled on a slabbing mill or a blooming mill into slabs or sheet bars. The slabs or sheet bars are then conditioned prior to being hot rolled on a finishing mill. Alternatively, the steel may be continuous cast directly into slabs that are ready for hot rolling on a finishing mill. Sheet produced from slabs on continuous rolling mills is coiled directly off the mill. After they are descaled, these hot bands are cold rolled to the required thickness, and coils off the cold mill are either annealed and descaled or bright annealed. Belt grinding to remove surface defects is frequently required at hot bands or at an intermediate stage of processing. Full coils or lengths cut from coils may then be lightly cold rolled on either dull or bright rolls to produce the required finish. Sheet may be shipped in coils, or cut sheets may be produced by shearing lengths from a coil and flattening them by roller leveling or stretcher leveling.

Stainless steel strip coils made of ASTM A240 type 316L, supplied to Miskolc city, Hungary.

Cold-rolled stainless steel strip is manufactured from hot-rolled, annealed, and pickled strip (or from slit sheet) by rolling between polished rolls. Depending on the desired thickness, various numbers of cold-rolling passes through the mill are required for effecting the necessary reduction and securing the desired surface characteristics and mechanical properties. Hot-rolled stainless steel strip is a semi-finished product obtained by hot-rolling slabs or billets and is produced for conversion to finished strip by cold rolling. Strips of stainless steel 304/304L & 316/316L are usually either annealed, annealed and skin passed, or bright annealed depending on requirements. For strips, edge condition is often more important than it usually is for sheet. Strips can be furnished with various edge specifications: No. 1 edge—A rolled edge, either round or square as specified. No. 3 Edge—An edge produced by slitting. No. 5 Edge—An approximately square edge produced by rolling or filing after slitting.

| Element | TP304 | TP304L |

|---|---|---|

| C | ≤0.08 | ≤0.03 |

| Mn | ≤2.00 | ≤2.00 |

| P | ≤0.045 | ≤0.045 |

| S | ≤0.030 | ≤0.030 |

| Si | ≤0.75 | ≤0.75 |

| Ni | 8.0-11.0 | 8.0-12.0 |

| Cr | 18.0-20.0 | 18.0-20.0 |

| N | ≤0.10 | ≤0.10 |

| Element | 316 | 316L |

|---|---|---|

| C | ≤0.08 | ≤0.03 |

| Mn | ≤2.00 | ≤2.00 |

| P | ≤0.045 | ≤0.045 |

| S | ≤0.030 | ≤0.030 |

| Si | ≤0.75 | ≤0.75 |

| Ni | 10.0-14.0 | 10.0-14.0 |

| Cr | 16.0-18.0 | 16.0-18.0 |

| Mo | 2.00-3.00 | 2.00-3.00 |

| N | ≤0.10 | ≤0.10 |

| Mechanical Requirements | TP304 | TP304L |

|---|---|---|

| Tensile Strength, min. MPa [ksi] | 515 [75] | 485 [70] |

| Yield Strength, min. MPa [ksi] | 205 [30] | 170 [25] |

| Elongation in 2" min. % | 40 | 40 |

| Brinell Hardness max. HBW | 201 | 201 |

| Rockwell Hardness Max. HRBW | 92 | 92 |

| Mechanical Requirements | Gr. 316 | Gr. 316L |

|---|---|---|

| Tensile Strength min. MPa [ksi] | 515 [75] | 485 [70] |

| Yield Strength min. MPa [ksi] | 205 [30] | 170 [25] |

| Elongation in 2", min. % | 40 | 40 |

| Brinell Hardness max. HBW | 217 | 217 |

| Rockwell Hardness max. HRBW | 95 | 95 |