Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

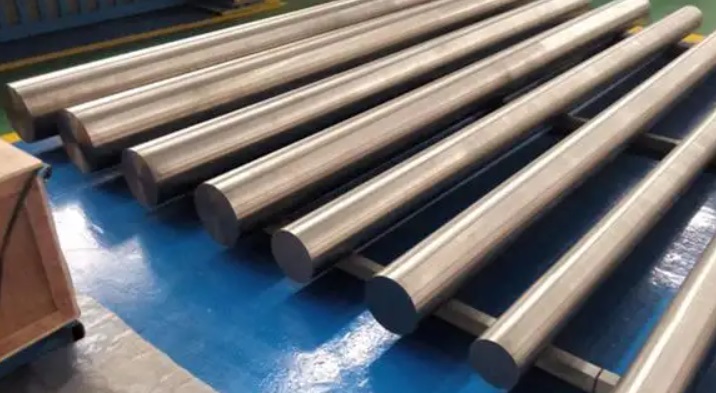

A glance at the machining workshop for titanium bars and billets.

Titanium bars and billets generally refer to those made from unalloyed or commercially pure titanium Grade 1, Grade 2, Grade 3 and Grade 4 in accordance with ASTM B348 or its identical standard specification ASME SB-348. A titanium bar is a hot rolled, forged, extruded or cold worked semi-finished solid section product whose cross section area is equal to or less than 16 inch2; rectangular bar must be no greater than 10″ in width and greater than 0.1875″ in thickness. A titanium billet is a solid semi-finished section hot worked or forged from an ingot, with a cross sectional area greater than 16 inch2 whose width is less than five times its thickness.

ASTM B348 bars and billets made of unalloyed titanium Grade 1, 2, 3, 4 are commercially pure titanium. They provide excellent resistance to general and localized corrosion attack under most oxidizing, neutral and inhibited reducing conditions in aqueous environments. Titanium is also notable for its outstanding resistance to chlorides and other halides generally present in most process streams. In addition, titanium resists other malicious phenomenon including steam and particle erosion, crevice corrosion, galvanic attack and MIC. These commercially pure titanium billets and bars are widely used in many petrochemical and chemical, sewage treatment, water desalination, as well as power generation applications. They are also the preliminary base material for further extruding, forging, and piercing operations to attain more complicated industrial products such as pipes, flanges, and fittings.

The 2-tonnage vacuum consumable electrode furnace for melting and remelting of titanium ingots.

ASTM B348 Grade 1, Grade 2, Grade 3 and Grade 4 are the four classical commercially pure titanium grades, which have varying amounts of impurities such as carbon, hydrogen, iron, nitrogen, and oxygen. Due to the small amounts of interstitial impurities, it is not convenient to distinguish between various grades of unalloyed titanium on the basis of chemical analysis. Titanium mill products are more readily distinguished by mechanical properties since the varying impurity amounts significantly affect the mechanical properties of pure titanium. Besides, unalloyed titanium grades have a high specific strength: yield strength comparable to austenitic stainless steels with density only about 55% of the steel. This makes industrial parts made from titanium billets or bars much lighter than expected.

ASTM B348 titanium grade 2 round bars, Φ101.6mm x 2m, supplied to Saudi Arabia.

ASTM B348 titanium Grade 1 has the highest purity, lowest strength, and best room-temperature ductility and formability of the four unalloyed titanium grades. It should be used where maximum formability is required and where low iron and interstitial contents might enhance corrosion resistance in highly oxidizing to mildly reducing environments, including chlorides. In addition, Grade 1 titanium bars and billets have good impact properties at low temperatures. ASTM B348 titanium Grade 2 is the workhorse for industrial applications, having a guaranteed minimum yield strength 275 MPa [40 ksi] and good ductility and formability. As the impurities content (especially oxygen and iron) goes higher, ASTM B348 titanium Grade 3 and Grade 4 have much higher yield strength but slightly reduced corrosion resistance.

| Element | ASTM B348 Ti Grade 1 | ASTM B348 Ti Grade 2 |

| C | ≤0.08 | ≤0.08 |

| O | ≤0.18 | ≤0.25 |

| N | ≤0.03 | ≤0.03 |

| H | ≤0.015 | ≤0.015 |

| Fe | ≤0.20 | ≤0.30 |

| O.E.E | ≤0.1 | ≤0.1 |

| O.E.T | ≤0.4 | ≤0.4 |

| Ti | Remaining | Remaining |

| Element | ASTM B348 Ti Grade 3 | ASTM B348 Ti Grade 4 |

| C | ≤0.08 | ≤0.08 |

| O | ≤0.35 | ≤0.40 |

| N | ≤0.05 | ≤0.05 |

| H | ≤0.015 | ≤0.015 |

| Fe | ≤0.30 | ≤0.50 |

| O.E.E | ≤0.1 | ≤0.1 |

| O.E.T | ≤0.4 | ≤0.4 |

| Ti | Remaining | Remaining |

| Test | ASTM B348 Grade 1 | ASTM B348 Grade 2 |

| Tensile Strength min. MPa [ksi] | 240 [35] | 345 [50] |

| Yield Strength min. MPa [ksi] | 138 [20] | 275 [40] |

| Elongation in 2", min. % | 24 | 20 |

| Reduction of Area, min. % | 30 | 30 |

| Test | ASTM B348 Grade 3 | ASTM B348 Grade 4 |

| Tensile Strength min. MPa [ksi] | 450 [65] | 550 [80] |

| Yield Strength min. MPa [ksi] | 380 [55] | 483 [70] |

| Elongation in 2", min. % | 18 | 15 |

| Reduction of Area, min. % | 30 | 25 |

The manufacture of ASTM B348 titanium billets and bars requires titanium sponge as the raw material. The titanium sponge is attained by a Kroll’s process, which involves reduction of titanium tetrachloride with magnesium under an inert gas atmosphere. The attained titanium sponge is then be melted and remelted in a vacuum consumable electrode furnace or vacuum arc remelting furnace to produce an ingot. The ingot is then subjected to the multiple-passes hot rolling or forging operations at the temperature above its β transus temperature to attain desired bar or billet that conforms to the requirements of ASTM B348.

The forging of ASTM B348 Gr.3 titanium bar. Photo taken in a workshop in Baoji city, Shanxi Province.

Generally, ASTM B348 unalloyed titanium bars and billets shall be annealed after forming operations: the products shall be heated completely to a temperature between 600°C and 700°C, holding for 1~4 hours depending on the thickness of the workpiece, and then cooled in air. Descaling process shall be conducted to ensure that the titanium bar or billet is free of injurious external and internal imperfections.