Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

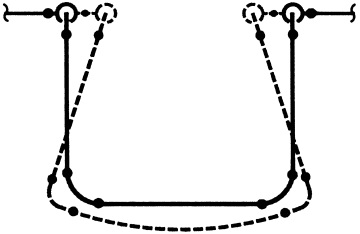

When the piping is constructed or installed, usually no movement is favorable since it would induce excessive stress in normal piping arrangements. However, thermal and mechanical movements, caused by various internal and/ or external factors, are generally inevitable in any piping system. The possible piping movements include axial compression/ contraction, axial extension/ expansion, lateral deflection, angular movement, torsional movement, as well as vibration, etc. Among all piping movements, thermal expansion and contraction are more prevalent. In piping design, elbows, bends and piping loops normally provide adequate flexibility for piping thermal expansion and contraction as illustrated in Figure-1 and Figure-2.

Figure-1: typical piping layout of U-type pipe loops to absorb piping expansion in an oil refinery.

Figure-2: thermal expansion will cause the two ends of the pipe to grow toward one another resulting in the distortion of the piping loop, whereupon the expansion of pipe is absorbed.

However, in some cases this flexibility may not be adequate. Moreover, there might not be enough space for the piping loop layout. As a solution, a flexible piping component may be used to absorb relative piping movements. This component is defined as “expansion joint“, also known as “piping compensator“. The expansion joints can be jointed to the line by direct butt welding or flange connection.

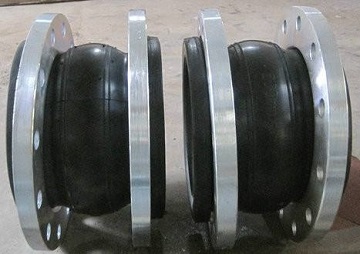

Expansion joints can be classified into metallic expansion joints and non-metallic expansion joints according to its material. In engineering practice, the classification is usually based on a combination of construction, material and function. In this term, there are 6 main categories available: slip type expansion joint (also known as sleeve expansion joint), ball expansion joint, rotary expansion joint, metal bellows expansion joint, rubber expansion joint, and custom-design/ composite expansion joint. Among all types of expansion joints, metal bellows expansion joints and rubber expansion joints take predominance in modern piping industry. This doesn’t exclude other types finding their use in specific industries.

Various metallic expansion joints: bellows expansion joints and slip-type expansion joints.

Both ASME B31 Codes and ASME Boiler and Pressure Vessel Codes have endorsed the use of expansion joints in thermal piping. Metal bellows expansion joints are generally designed in accordance with Standards of The Expansion Joint Manufacturers Association (EJMA). Non-metallic expansion joints shall be designed in accordance with ASTM F1123. The Expansion Joints Piping Handbook from Fluid Sealing Association (FSA) provides detailed guidance on rubber expansion joints. Besides, our expansion joint manufacturers can also meet other main industrial standards related to JIS, DIN, BS, EN, AS, GB/T, JB/T, HG/T, and GOST etc.

Rubber expansion joints, flange connection.

To apply an expansion joint (or piping compensator) in a piping system, one shall not only know the dimensional and engineering data concerning the joint type but also shall have clear knowledge of installation layouts, locations, movements, forces, stresses, moments, cycle-life expectancy, and effects of corrosion, erosion, and testing.

The metallic part of the expansion joint may be made from carbon steel, alloy steel, stainless steel, nickel alloy, aluminum alloy, titanium and zirconium alloy, or copper alloy, etc. The non-metallic part of the expansion joint may be made from natural or synthetic rubber, plastic, ceramic, or fabric cord, etc. Expansion joints (piping compensators) are widely used in a variety of industries such as thermal power plant, oil & gas, offshore platform, civil water supply, sewage treatment, district heating supply, etc.