Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

Figure-1: metal-reinforced rubber seated knife gate valves with various actuation: A-handwheel; B-gear operator; C-pneumatic actuator; D-hydraulic actuator; E-electric actuator.

The MB-series rubber seated knife gate valves we supply have the following design features: (1) The one-piece integral body design minimizes the possibility of shell leakage while maintaining cost effective. (2) The full-port flow passage is formed by compacting two identical rubber seat rings from opposite direction of the body. The full port design minimizes pressure drop and ensures smooth flow characteristics. (3) Due to the double-seat arrangement, the valve can handle bidirectional flows. (4) The rubber seat ring is embedded with a metal ring. This metal reinforcement imparts sufficient rigidity and strength to the seat ring and improves sealing performance as well as the life span. (5) The end face of the rubber seat protrudes out from the valve body acting as a gasket when the valve is connected to pipeline flanges. (6) Double-bearing arrangement for the stem to reduce the operation torque. (7) PTFE scrapers are furnished at the top of the disc to clean the disc during operation.

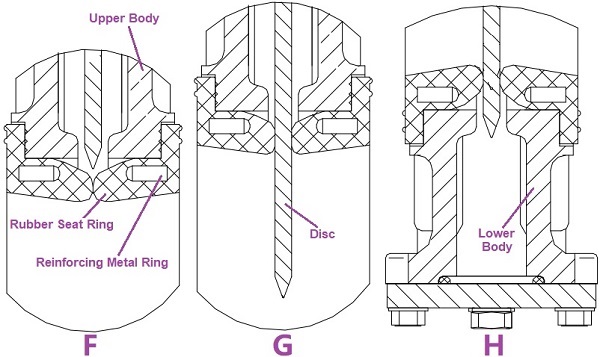

Figure-2: How does the MB-series rubber seated knife gate valve work? F: fully open; G: closing process; H: fully closed.

As illustrated in F of Figure-2, two metal-reinforced rubber seats are mounted from two opposite sides of the valve body. When the MB-series rubber seated knife gate valve is in fully open position, the two rubber seat rings are in close and firm contact along their periphery hence a full-port flow passage is formed. The fluid can flow through unimpededly. The disc can even be replaced or maintained in this working condition without obstructing the function of the pipeline. When the MB-series rubber seated knife gate valve is in a closing process, as shown in G & H of Figure-2, the disc is driven to penetrate through the contact surfaces between the rubber seats in the upper body, then through that in the lower body. The zero-leakage tightness is achieved from two directions. During the on-off operation, some fluid may permeate into the lower body cavity along the disc, hence routine drainage may be required.

The MB-series rubber seat knife gate valves are especially suitable for slurry and viscous fluid in mining industry and pulp and paper industry.

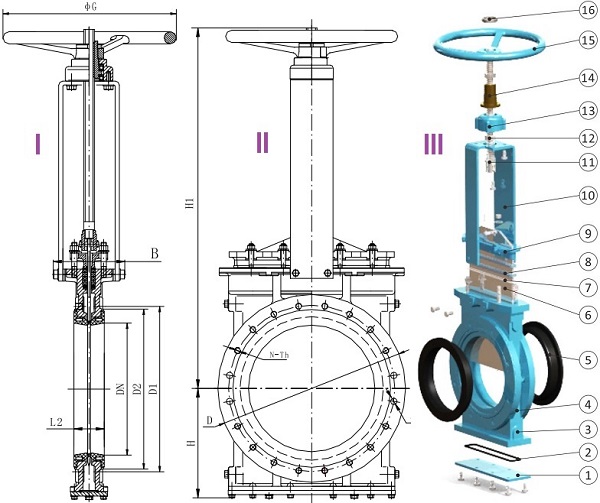

The G.A. drawing of a MB-series rubber seated knife gate (handwheel operated). I: left view; II: front view; III: 3D explosive view.

| Part No. | Part Name | Material |

|---|---|---|

| 1 | Bottom Cover | Carbon Steel SS304/SS316 |

| 2 | Bottom Gasket | NBR, EPDM |

| 3 | Drainage Hole | - |

| 4 | Body | GGG40/WCB CF8/CF8M CF3/CF3M |

| 5 | Seat Ring | Natural Rubber EPDM |

| 6 | Disc | SS304/SS316 Duplex 2205 Gr. F53, F55 |

| 7 | Scraper | PTFE |

| 8 | Packing | PTFE, EPDM Graphite |

| 9 | Gland | WCB/CF8 |

| 10 | Yoke | SS304/SS316 Carbon Steel |

| 11 | Stem | 2Cr13, SS304 SS420, SS316 |

| 12 | Bearing | GCr15 |

| 13 | Connector | GGG40/WCB |

| 14 | Stem Nut | Brass |

| 15 | Handwheel | M.I./D.I./C.I. |

| 16 | Nut | SS201/SS304 |

| Size | L1 | L2 | ΦG |

|---|---|---|---|

| 2" | 52 | 57 | 180 |

| 2.5" | 52 | 57 | 180 |

| 3" | 55 | 62 | 220 |

| 4" | 55 | 62 | 220 |

| 5" | 61 | 69 | 240 |

| 6" | 61 | 69 | 240 |

| 8" | 74 | 81 | 300 |

| 10" | 74 | 83 | 320 |

| 12" | 82 | 96 | 350 |

| 14" | 82 | 96 | 400 |

| 16" | 95 | 109 | 450 |

| 18" | 95 | 109 | 500 |

| 20" | 118 | 127 | 550 |

| 22" | 118 | 127 | 550 |

| 24" | 118 | 127 | 600 |

| Size | H | H1 | B |

|---|---|---|---|

| 2" | 125 | 360 | 105 |

| 2.5" | 135 | 380 | 105 |

| 3" | 145 | 410 | 105 |

| 4" | 155 | 445 | 105 |

| 5" | 175 | 490 | 105 |

| 6" | 195 | 560 | 140 |

| 8" | 225 | 630 | 140 |

| 10" | 260 | 760 | 160 |

| 12" | 300 | 885 | 160 |

| 14" | 330 | 950 | 185 |

| 16" | 345 | 1040 | 185 |

| 18" | 395 | 1180 | 200 |

| 20" | 420 | 1320 | 230 |

| 22" | 490 | 1420 | 230 |

| 24" | 530 | 1560 | 255 |

Only structural dimensions for sizes 2″~24″ are provided. For sizes larger than 24″ or for valves with other actuation, please contact us for an engineered drawing. Flange drilling dimensions shall be in accordance with EN1092-1 PN10 & PN16, ASME B16.5 Class 150, BS4504 PN10 & PN16, BS 10 Table D & Table E.