Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

ASTM A213 Gr. TP316L seamless tubes can be further classified as TP316L boiler tubes, TP316L superheater tubes, and TP316L heat exchanger tubes, according to the service it is used for. The tubing is usually specified by outside diameter and minimum wall thickness, or average wall thickness. Sometimes the wall thicknesses are specified by Birmingham Wire Gauge (B.W.G) numbers.

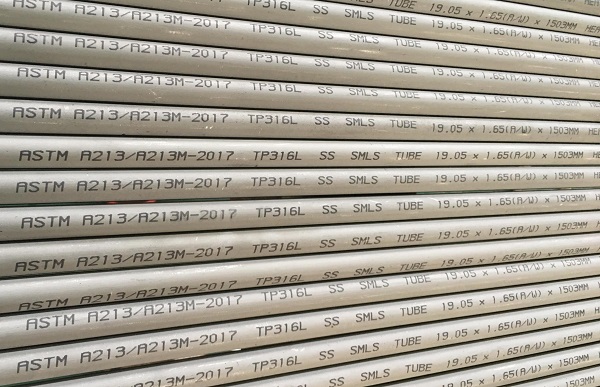

ASTM A213 Gr. TP316L seamless tubes, (o.d.)19.05 mm x (w.t.)1.65 mm x (l)1503 mm.

Grade TP316L of ASTM A213 has the nominal composition of 16Cr-12Ni-2Mo with UNS designation of S31603. It is the modified version of the most common TP304 stainless steel with addition of molybdenum, increased nickel content and lower chromium content. The addition of molybdenum in TP316L provides pitting resistance in phosphoric and acetic acids and dilute chloride solutions, as well as corrosion resistance in sulfurous acid (H2SO3). As an extra-low-carbon stainless steel, TP316L is resistant to carbide precipitation in the 425°C to 870°C [800°F to 1600°F] range and can thus undergo normal welding without reduction in corrosion resistance. However, when it is heated and held in the sensitizing temperature range for an extended/ prolonged period, chromium carbides precipitate in significant quantities. This leads to the susceptibility of the steel to intergranular corrosion. Thus, ASTM A213 TP316L tubing is generally recommended for use below 425°C [800°F].

| Element | % by Mass |

|---|---|

| C | ≤0.035 |

| Mn | ≤2.00 |

| P | ≤0.045 |

| S | ≤0.030 |

| Si | ≤1.00 |

| Cr | 16.0-18.0 |

| Ni | 10.0-14.0 |

| Mo | 2.00-3.00 |

| Tensile & Hardness Tests | Requirements |

|---|---|

| Tensile Strength min. MPa [ksi] | 485 [70] |

| Yield Strength min. MPa [ksi] | 170 [25] |

| Elongation in 2", min. % | 35 |

| Brinell Hardness max. HBW | 192 |

| Vickers Hardness max. HV | 200 |

| Rockwell Hardness max. HRB | 90 |

The precision cold-rolling mill for the production of stainless steel seamless pipes & tubes, imported from SMS MEER (Germany), courtesy of TISCO.

Similar to the production process of ASTM A213 TP316Ti seamless tubing, TP316L seamless tubing shall be made by the seamless process and shall be either hot finished or cold finished. The tubes shall be furnished with solution annealing heat treatment: the tubing shall be soaked in furnace at the minimum temperature 1900°F [1040°C] for long enough period to achieve full austenitization. It shall be subsequently quenched in cold water. The ASTM A213 TP316L tubing may be furnished in several delivery conditions depending on clients’ requirements: solution annealed and pickled; solution annealed, pickled and then polished; bright annealed.

| ASME Boiler & Pressure Vessel Codes | ||

|---|---|---|

| Table | Section | Max. Temperature |

| Table 1A | I | 850°F |

| III - Cl.2 & 3 | 800°F | |

| VIII - Div.1 | 850°F | |

| Table 2A | III Div.1 Cl.1 & MC | 800°F |

| VIII Div.2 Cl.1 | 800°F | |

| Table 5A | VIII Div.2 | 800°F |

| Table 6A | IV | 500°F |

In addition, both ASME B31.1 – Power Piping and ASME B31.3 – Process Piping have endorsed the use of ASTM A213 TP316L seamless tubing. ASME B31.1 has specified the lower and upper design temperature limits as 100°F and 1200°F, respectively. ASME B31.3 has specified the minimum design temperature without impact testing requirement and the maximum design temperature as -425°F and 1500°F. Although the Codes permit the use of TP316L tubing at higher temperatures, it is always used for services below 425°C [800°F] in practice.