Product Categories

- Products (61)

ASTM A333 Grade 6 seamless pipe for low-temperature service, 16" STD (o.d.406 mm x w.t. 9 mm x 6000 mm, manufactured by BAOSTEEL.

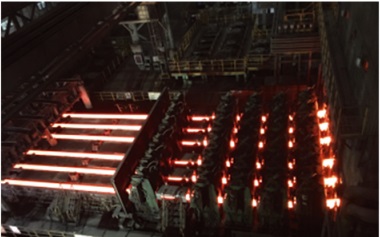

The cone-type piercing mill for the production of ASTM A333 Gr.6 seamless pipes, courtesy of BAOSTEEL.

The ASTM A333 Grade 6 low alloy steel seamless pipes are intended for low temperature services with minimum design temperature -45°C [-50°F] requiring notch toughness. They are usually furnished in nominal pipe size (NPS) and nominal wall thickness with schedule numbers in accordance with ASME B36.10M. They are often connected with flanges of ASTM A350 LF2 and butt-weld pipe fittings of ASTM A420 WPL6. Seamless pipes made from ASTM A333 Gr.6 are primarily used for the construction of pipelines in the production of ethylene, propylene, urea, ammonia, and N-P-K compound fertilizer. They may be involved in the scrubber, purification, desulfurization and degreasing processes in oil & gas, petrochemical, coal and pharmaceutical industries. They can also be used for the fabrication of cryogenic equipment as well as refrigeration houses.

| Element | Composition, wt. % |

|---|---|

| C | ≤0.30 |

| Mn | 0.29-1.06 |

| P | ≤0.025 |

| S | ≤0.025 |

| Si | ≥0.10 |

| Ni | ≤0.40 |

| Cr | ≤0.30 |

| Cu | ≤0.40 |

| V | ≤0.08 |

| Nb | ≤0.02 |

| Mo | ≤0.12 |

In terms of the influence on low temperature impact toughness, phosphorus (P) is the most detrimental element among C, Si, P, Si and N to the Charpy toughness of ASTM A333 Gr.6. Their amount shall be reduced to the smallest. Manganese, as well as the addition of small traces of nickel, vanadium, copper and niobium, can significantly reduce the critical brittle-ductile transition temperature and refine the grain, therefore, improve the impact toughness.

| Tensile Properties | Requirements (Longitudinal) | Requirements (Transverse) |

|---|---|---|

| Tensile Strength min. MPa [ksi] | 415 [60] | 415 [60] |

| Yield Strength min. MPa [ksi] | 240 [35] | 240 [35] |

| Elongation in 2", min. % | 30 | 16.5 |

Toughness, or ductility, is the ability of a material to resist impact, to withstand repeated reversals of stress, or to absorb energy when stressed beyond the elastic limit. Steel is normally considered to be a ductile material, however, it may shatter just as glass at certain low temperatures. The critical ductile-to-brittle transition temperature (CDBTT) for any steel is the temperature above which the steel behaves in a predominantly ductile manner and below which it behaves in a predominantly brittle manner. The low alloy steel pipe of ASTM A333 Gr.6 with a low CDBTT can be used at temperatures down to -45°C [-50°F]. It is important to verify that the pipe materials are impact tested and exhibit a sufficient high Charpy toughness.

The Charpy impact equipment for low temperature test in a lab.

The Charpy V-notch impact test shall be conducted at -45°C [-50°F] with three testing specimens in the size of 10 mm x 10 mm x 55 mm. The minimum average energy absorbed for three specimens shall be 18 J [13 ft*lbf], and the minimum energy absorbed for each specimen is 14 J [10 ft*lbf]. The actual tests have been done to three specimens which were taken from ASTM A333 Gr.6 seamless pipes produced by BAOSTEEL. The results listed in the table below indicate that the steel exhibits superior impact toughness, which is at least 20 times higher than the standard value.

| Item | Energy Absorption, J |

|---|---|

| Specimen 01 | 373 |

| Specimen 02 | 363 |

| Specimen 03 | 355 |

| Average of Three | 364 |

| Minimum of Three | 355 |

The ASTM A333 Gr.6 seamless pipes can be manufactured by the seamless process from scratch: EAF melting ➡ ladle furnace remelting ➡ VOD ➡ continuous casting ➡ blooming ➡ bright annealing ➡ piercing ➡ cold drawn ➡ heat treatment ➡ straightening & cutting ➡ NDT (ET & UT) ➡ visual examination & dimensional inspection ➡ properties inspection ➡ packaging.

Continuous cast for pipe billets, courtesy of BAOSTEEL.

The ASTM A333 Gr.6 seamless pipe can be normalized by heating the pipe to a uniform temperature of no less than 1500°F [815°C] and cool in air. Or it can be heat treated by heating the pipe to a uniform temperature of no less than 1500°F [815°C], followed by quenching in liquid and reheating to a suitable tempering temperature.

| ASME Codes | ASTM A333 Gr.6 |

|---|---|

| B31.1 | Yes |

| B31.3 | Yes |

| B31.4 | Yes |

| B31.5 | Yes |

| 31.8 | Yes |

| Section I | Yes |

| Section III | Yes |

| Section VIII-1 | Yes |

| Section XII | Yes |

| Section VIII-2 | Yes |