Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

Butterfly valves are valves in which the disc rorates around the valve stem to open and close. They use the disc as the closure element, the rotation angle is between 0° and 90°. The butterfly valve reaches maximum opening when disc is rotated to 90°. Butterfly valve is often used in the furnace, gas, natural gas, liquefied petroleum gas, chemical smelting and other engineering systems to transport a variety of corrosive, non-corrosive fluid media on the pipeline, used to adjust and cut off the flow of the medium.

A typical butterfly valve

Butterfly valves can be designed and manufactured in accordance with a variety of major standards and Codes including GB/T 12238 (Flanged and wafer resilient seal butterfly valves), API 609 (Butterfly valves: Double Flanged, Lug- and Wafer-Type), BS 5155 (Specification for butterfly valves), ISO 5752 (Metal valves for use in flanged pipe systems — Face-to-face and centre-to-face dimensions), ISO 10631 (Metallic butterfly valves for general purposes), MSS SP-67 (Butterfly Valves), MSS SP-68 (High pressure butterfly valves with offset design), JIS B 2032 (Wafer type rubber-seated butterfly valves), JB/T (Metallic sealing butterfly valve), etc.

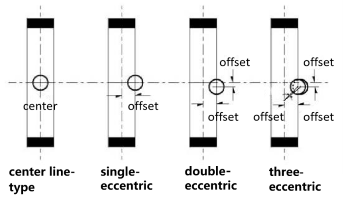

Butterfly valves can be divided into four types according to their construction: center line-type butterfly valves, single-eccentric center butterfly valve, double-eccentric center butterfly valve and three-eccentric center butterfly valve. Center line-type butterfly valve, which the butterfly plate rotation center is located in the center of the valve body, butterfly valve is located in the butterfly plate seal part. Double offset butterfly valve is the popular butterfly valve. This valve has two off-center stems. The first offset is that the axis of the shaft is behind the center line of the disc sealing point. The second offset is that the axis of the shaft is off the center of the valve. The three eccentric butterfly valves have three offsets. Two of these are placed in positions similar to the double-offset butterfly valve, and the third offset is the geometry of the seat surface, resulting in the conical shape of the disc and seat. The cone Angle and two eccentric shaft offsets allow the disc to seal frictionless on the seat.

G.A drawings for center and offset

Butterfly valves can also be classified according to different form of sealing. The first is forced sealing butterfly valve include two types: A. elastic sealing butterfly valve. Seal pressure is produced by the disc squeezing the seat when the valve is closed and the seat or disc is resilient; B. Torque sealing butterfly valve. The seal pressure is generated by the torque applied to the valve shaft. The second is pressure seal butterfly valve. Which the seal pressure is caused by the charging of the cartridge seal element on the seat or disc. The last is self-sealing butterfly valve. The seal pressure is generated automatically by the medium pressure.

Butterfly valves classification according to the different seal material: soft-seal butterfly valve and hard sealing butterfly valve. Soft-seal butterfly valve, which the sealing pair is composed of nonmetallic soft material and nonmetallic soft material. Sealing material using soft material such as: rubber, polytetrafluoroethylene, etc.. This kind of seal sealing performance is better, but not resistant to high temperature, easy to wear, mechanical poor. Hard sealing butterfly valve refers to the sealing material is made of metal: copper seal, stainless steel, nickel base alloy. Seat seal surface layer surfacing welding temperature and corrosion resistant alloy material. This kind of butterfly valve sealing performance with high temperature resistance, light operation, open and close without friction, improve the sealing performance of the butterfly valve, and extend the service life.

Butterfly valve types classified by connection: wafer butterfly valve, flanged butterfly valve, lug butterfly valve and welded butterfly valve.

Butterfly valves classification according to the operating temperature: high temperature butterfly valve, t>450°C; medium-temperature butterfly valve, 120°C <t <450°C; normal temperature butterfly valve, -40°C <t <120°C; low temperature butterfly valve, -100°C <t <-40°C; cryogenic butterfly valve, t <-100°C.

Butterfly valves type classified by the working pressure: vacuum valve, working pressure is lower than standard atmospheric heap; low pressure valve, nominal pressure PN<1.6MPa; medium pressure valve, nominal pressure is 2.5–6.4MPa; high pressure valve, nominal pressure is 10.0–80.0MPa; super high pressure valve, nominal pressure PN> 100MPa.