Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

The cast iron gate valve, furnished with cast gray iron or ductile iron body and bonnet, is a linear-motion manual valve that uses a typically flat closure element perpendicular to the process flow, which slides into the flow stream to provide shutoff. It is designed primarily for on-off services as a block valve, where the valve is operated frequently. Cast iron gate valves do not handle throttling applications well because they provide inadequate control characteristics. They are widely applied for low-pressure and ambient-temperature utility services such as water supply, sewage treatment, gas supply, district heating piping, irrigation projects, air conditioning systems, as well as food processing industry, chemical and petrochemical industry, pharmaceutical and powder industry.

Cast iron gate valves: OS&Y rising stem (left) and non-rising stem (right); handwheel operated.

Cast iron gate valves may be optionally furnished with a series of construction characteristics:

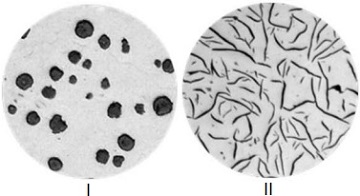

The body and bonnet of the cast iron gate valve shall be made of gray irons or ductile irons, which are classified according to the microstructure of graphite shape in its metallurgical pahse. The carbon that exceeds the solubility in austenite precipitates as flake (lamellar) graphite in gray iron, while that presents as tiny spheres (nodules) in ductile iron. The fracture surface of gray iron exhibits gray appearance, while that of ductile rion exhibits silver-gray appearance. Influenced by the graphite morphology, ductile iron is much stronger and has higher elongation than gray iron. However, due to the higher purity requirement on raw material and additives introduced in molten iron before casting, the cost of ductile iron is relatively higher than gray iron.

The microstructure of graphite in ductile & gray irons according to ASTM A247: Type I – spheroidal (nodular) graphite in ductile irons; Type II – flake (lamellar) graphite in gray irons.

For metal-to-metal seating surfaces, the seating materials for cast iron gate valves may be cast iron, aluminum bronze, bronze, or brass. For soft (resilient) seated cast iron gate valves, the seating materials may be rubber or plastics such as natural rubber, EPDM, NBR, PTFE, etc. The stem material shall be stainless steel, brass, or bronze. Handwheels may be made from gray iron, ductile iron, or malleable iron at manufacturer’s option. The packing materials usually are graphite and the bolting materials usually are chosen from high strength carbon steel or low alloy steel. The selection of material for each valve part shall be determined by a set of comprehensive conditions covering working pressure, working temperature, working fluids or gases, and flow rates, etc.

Cast iron gate valves may be designed and manufactured in accordance with a series of international standards:

Located in different industrial zones in China, there are hundreds of cast iron gate valve manufacturers that can perform massive cast-iron production. Specifically, they are located in Botou and Xintai of Hebei province, Tianjin city, Weifang and Laiwu in Shandong province, Chizhou and Wuhu in Anhui province. Shijiazhuang Metalsin Pipeline Tech Co., Ltd conducts a very strict supply chain management system, which allows us to provide quality cast iron gate valves in full spectrum with most competitive prices.