Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

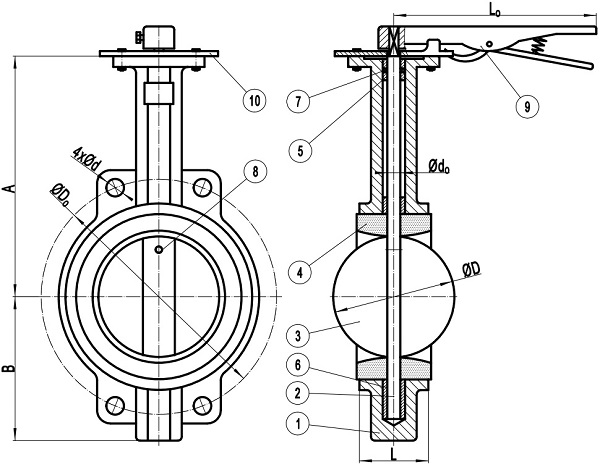

The technical drawing of a MSS SP 67 wafer type butterfly valve, made of cast iron. handle/ lever operated, concentric (centerline) design, pinned disc, soft seated.

The MSS SP 67 cast iron wafer butterfly valve, either furnished with ductile iron or grey iron body, has a flangeless flat body that has a minimum face-to-face dimension, which is equal to twice the required wall thickness plus the width of the packing box. When used in piping connection, the valve will be clamped between two pipe flanges using through bolting. The MSS SP 67 wafer butterfly valve is a quarter-turn (0° to 90°) rotary-motion valve that uses a round disc as the closure member. When it is fully open (at 90° position), the disc remains parallel to the piping flow direction and extends into the pipe itself. When the valve is being closed, the disc rotates to become perpendicular to the direction of flow and acts as a dam to stop or reduce the flow. At the fully closed position (0° position), the seating surfaces of the disc rim and the rubber seat are in full contact with each other. The butterfly valve can be used not only for on-off service but also throttling service since it provides sensitive flow control when open between about 15° to 70°. Their great advantage is their narrow width and light weight, low cost, frictionless rotation that require little torque, and the simplicity of their design. Although MSS Sp 67 allows for sizes from NPS 1/2 through NPS 72, wafer type butterfly valves are more commonly applied in the specific sizes from 2″ to 12″.

Ductile iron wafer type butterfly valves made in accordance with MSS SP 67.

| Item No. | Part Name | Material Spec. |

|---|---|---|

| 1 | Valve Body | Cast Iron Ductile Iron |

| 2 | Stem | SS 304, SS316, SS 410, SS431 |

| 3 | Disc | SS 304, SS 316, Bronze, Al-Bronze Ductile Iron + Ni Plated |

| 4 | Seat | EPDM, NBR, Viton, PTFE |

| 5 | Short Bushing | PTFE, Bronze |

| 6 | Long Bushing | PTFE, Bronze |

| 7 | O-Ring | EPDM, NBR |

| 8 | Tapered Pin | SS410 |

| 9 | Handle/ Lever | Cast Iron, Aluminum |

| 10 | Indicator | Carbon Steel |

| Size | B mm | A mm | L mm |

|---|---|---|---|

| 2" | 80 | 161 | 42 |

| 2-1/2" | 89 | 175 | 45 |

| 3" | 95 | 181 | 45 |

| 4" | 114 | 200 | 51 |

| 5" | 127 | 213 | 55 |

| 6" | 139 | 226 | 55 |

| 8" | 175 | 260 | 60 |

| 10" | 203 | 292 | 67 |

| 12" | 242 | 337 | 76 |

| 14" | 267 | 368 | 76 |

| 16" | 316 | 400 | 102 |

| 18" | 334 | 422 | 114 |

| 20" | 370 | 480 | 127 |

| 22" | 433 | 533 | 151 |

| 24" | 468 | 562 | 151 |

| 26" | 484 | 540 | 172 |

| 28" | 530 | 626 | 165 |

| 30" | 565 | 660 | 167 |

| 32" | 602 | 666 | 188 |

| 36" | 661 | 722 | 203 |

| 40" | 724 | 806 | 216 |

| 48" | 869 | 938 | 276 |

Structural dimensions for MSS SP 67 wafer type butterfly valves (cast iron or ductile iron). The drilling dimensions shall be compatible for use with flanges conforming to one of the standards: ASME B16.1 Class 25, Class 125, Class 250; ASME B16.5 Class 150 and Class 300; ASME B16.24 Class 150; ASME B16.42 Class 150 and Class 300; AWWA C207.