Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

ASTM A387 Gr.11 Class 2 (1.25Cr-0.5Mo-Si steel) plates for boiler construction, produced by WUSTEEL.

The 1.25Cr-0.5Mo (also known as “1-1/4Cr-1/2Mo”) steel is a typical low alloy heat-resistant steel of the Cr-Mo steel family. It is widely used for applications at elevated temperatures. The figures “1.25” and “0.5” denote the nominal chemical composition of chromium and molybdenum alloying elements respectively. The chromium provides improved oxidation and corrosion resistance, and, the molybdenum increases creep strength at elevated temperatures. In ASME Codes, the 1.25Cr-0.5Mo generally refers to castings. Various wrought 1.25Cr-0.5Mo steels are furnished with necessary addition (0.5~1.0%) of silicon element, thus, are designated as “1.25Cr-0.5Mo-Si“. The silicon increases the elevated-temperature strength of steel. It also increases the resistance to scaling of the low-chromium steels in air at elevated temperatures. The 1.25Cr-0.5Mo steel may be furnished in annealed, normalized and tempered, or quenched and tempered condition.

| Product Forms | Standards & Grades |

|---|---|

| Castings | ASTM A217 WC6 ASME SA-217 WC6 |

| Cast Pipes | ASTM A426 CP11 ASME SA-426 CP11 |

| Bars | ASTM A739 B11 ASME SA-739 B11 |

| Forgings | ASTM A182 F11 ASME SA-182 F11 ASTM A336 F11 ASME SA-336 F11 |

| Seamless & Welded Fittings | ASTM A234 WP11 ASME SA-234 WP11 |

| Seamless Tubes | ASTM A213 T11 ASME SA-213 T11 |

| Welded Tubes | ASTM A250 T11 ASME SA-250 T11 |

| Seamless Pipes | ASTM A335 P11 ASME SA-335 P11 |

| Welded Pipes | ASTM A691 1.25Cr ASME SA-691 1.25Cr |

| Forged Pipes | ASTM A369 FP11 ASME SA-369 FP11 |

| Plates | ASTM A387 11 ASME SA-387 11 |

The 1.25Cr-0.5Mo (1.25Cr-0.5Mo-Si) steels can be provided in a variety of product forms in accordance with corresponding ASTM/ ASME standard specifications.

The density of 1.25Cr-0.5Mo steel is 7750 kg/m3, and the Poisson’s ratio is 0.30. The melting temperature range is 2600°F-2800°F. The typical values of thermal expansion (instantaneous, mean, and linear), thermal conductivity, thermal diffusivity, and modulus of elasiticity of the 1.25Cr-0.5Mo steel are listed in tables below. These values are listed as a function of temperature from 20°C to as high as 825°C.

| Temp. °C | A | B | C |

|---|---|---|---|

| 20 | 11.5 | 11.5 | 0 |

| 50 | 12.0 | 11.8 | 0.35 |

| 75 | 12.3 | 11.9 | 0.65 |

| 100 | 12.7 | 12.1 | 0.97 |

| 125 | 12.9 | 12.3 | 1.3 |

| 150 | 13.2 | 12.4 | 1.6 |

| 175 | 13.5 | 12.6 | 2.0 |

| 200 | 13.8 | 12.7 | 2.3 |

| 225 | 14.0 | 12.9 | 2.6 |

| 250 | 14.3 | 13.0 | 3.0 |

| 275 | 14.6 | 13.2 | 3.4 |

| 300 | 14.9 | 13.3 | 3.7 |

| 325 | 15.1 | 13.4 | 4.1 |

| 350 | 15.4 | 13.6 | 4.5 |

| 375 | 15.7 | 13.7 | 4.9 |

| 400 | 15.9 | 13.8 | 5.3 |

| 425 | 16.1 | 14.0 | 5.7 |

| 450 | 16.4 | 14.1 | 6.1 |

| 475 | 16.5 | 14.2 | 6.5 |

| 500 | 16.7 | 14.4 | 6.9 |

| 525 | 16.8 | 14.5 | 7.3 |

| 550 | 16.9 | 14.6 | 7.7 |

| 575 | 17.0 | 14.7 | 8.2 |

| 600 | 17.0 | 14.8 | 8.6 |

| 625 | 17.1 | 14.9 | 9.0 |

| 650 | 17.1 | 15.0 | 9.4 |

| 675 | 17.1 | 15.1 | 9.9 |

| 700 | 17.1 | 15.1 | 10.3 |

| 725 | 17.1 | 15.2 | 10.7 |

| 750 | 17.2 | 15.3 | 11.1 |

| 775 | 17.4 | 15.3 | 11.6 |

| 800 | 17.7 | 15.4 | 12.0 |

| 825 | 18.1 | 15.5 | 12.5 |

| Temp. °C | TC | TD |

|---|---|---|

| 20 | 41.0 | 11.87 |

| 50 | 40.8 | 11.47 |

| 75 | 40.7 | 11.16 |

| 100 | 40.6 | 10.88 |

| 125 | 40.5 | 10.60 |

| 150 | 40.4 | 10.33 |

| 175 | 40.3 | 10.08 |

| 200 | 40.1 | 9.82 |

| 225 | 39.8 | 9.57 |

| 250 | 39.5 | 9.32 |

| 275 | 39.1 | 9.07 |

| 300 | 38.7 | 8.82 |

| 325 | 38.3 | 8.57 |

| 350 | 37.8 | 8.32 |

| 375 | 37.3 | 8.06 |

| 400 | 36.8 | 7.81 |

| 425 | 36.3 | 7.55 |

| 450 | 35.8 | 7.29 |

| 475 | 35.3 | 7.03 |

| 500 | 34.8 | 6.77 |

| 525 | 34.4 | 6.50 |

| 550 | 33.9 | 6.24 |

| 575 | 33.4 | 5.97 |

| 600 | 32.8 | 5.69 |

| 625 | 32.2 | 5.42 |

| 650 | 31.6 | 5.14 |

| 675 | 30.7 | 4.78 |

| 700 | 29.1 | 4.37 |

| 725 | 27.6 | 3.83 |

| 750 | 26.7 | 2.69 |

| 775 | - | 1.26 |

| 800 | - | 5.06 |

| 825 | - | 7.74 |

| Temp. | E |

|---|---|

| -200 | 218 |

| -125 | 213 |

| -75 | 210 |

| 25 | 204 |

| 100 | 200 |

| 150 | 197 |

| 200 | 193 |

| 250 | 190 |

| 300 | 186 |

| 350 | 183 |

| 400 | 179 |

| 450 | 174 |

| 500 | 169 |

| 550 | 164 |

| 600 | 157 |

| 650 | 150 |

| 700 | 142 |

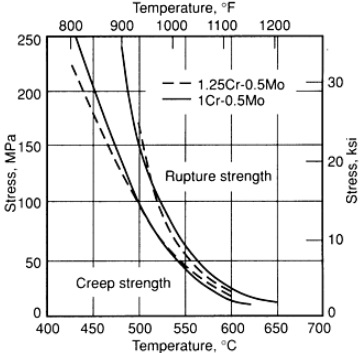

Illustration of creep strengths and rupture strengths of 1.25Cr-0.5Mo steels, compared to that of 1.0Cr-0.5Mo.

Due to the improved creep strength, 1.25Cr-0.5Mo steels can be used at temperatures as high as 649°C [1200°F]. It has comparable stress-rupture and creep properties at elevated temperatures as that of 1.0Cr-0.5Mo alloy steels.

| Temp. °F [°C] | Hardness, HB |

|---|---|

| Annealed | 156 |

| 1400 [760] | 149 |

| 1500 [815] | 156 |

| 1600 [870] | 179 |

| 1650 [900] | 187 |

| 1750 [955] | 229 |

| 1850 [1010] | 223 |

| 1950 [1065] | 212 |

Hardness is one of the key parameters of the heat-resistant steel. In order to determine the hardness values after air cooling, several pieces of round specimens (25 mm in diameter and 50 mm in length) were sliced longitudinally and heated. The hardness values are measured after air cooling from designated temperatures and presented in the table above.

Due to the huge consumption in many elevated-temperature applications, a complete supply chain for the 1.25Cr-0.5Mo steel has formed in China’s steel industry. It means that this steel is 100% recyclable and full spectrum of starting materials are commercially available. Thus, we can not only supply 1.25Cr-0.5Mo steels in various product forms such as casting, forging, pipe, tube, fitting, valve part, and pressure vessel, but also reduce the cost to the minimum.