Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

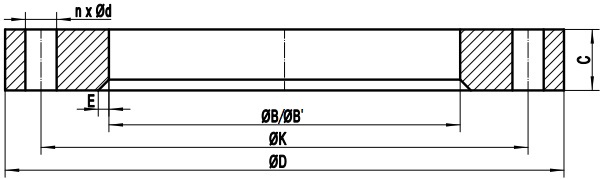

Figure-1: a typical drawing for EN 1092-1 type 02 & type 04 loose plate flanges. D: outside diameter of flange; K: diameter of bolt circle; d: diameter of bolt hole; n: number of bolting; E: chamfer; B: bore diameter of Type 02 flange; B’: diameter of Type 04 flange; C: flange thickness.

Both EN 1092-1 Type 02 and Type 04 flanges are loose plate flanges, which resemble the function of lap joint flanges of ASME B16.5. They can be viewed as a Type 01 slip-on plate flange with enlarged bore diameter and chamfered end to facilitate the insert of a lapped collar. Bolt holes shall be drilled along the periphery of the round plate in uniform distribution. There is some subtle difference between Type 02 and Type 04 loose plate flanges. The bore diameter of Type 04 is much larger than that of Type 02 of the same size and pressure rating. This is because the Type 04 flange shall always be able to accommodate the larger neck outside diameter of a tapered collar (Type 34).

| EN 1092-1 Loose Plate Flanges & Collars | |||

|---|---|---|---|

| Type 02 | Type 04 | Type 32 | Type 33 |

| Type 34 | Type 35 | Type 36 | Type 37 |

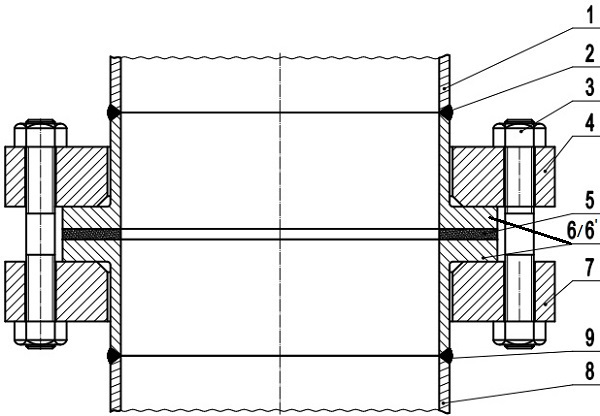

Figure-2: illustration of the “Type 02 + Type 35” flange joint in piping. It consists two pipes (1 & 8), two EN 1092-1 type 02 loose plate flanges (4 & 7), two EN 1092-1 type 35 weld ring necks/ collars (6 & 6′), a set of bolting (3), a flat gasket (5), and two butt welds (2 & 9) to attach the pipe to the collar.

Similar to the lap joint flange & stub end assembly, the EN 1092-1 Type 02 loose plate flange shall always be used with a Type 32, Type 33, Type 35, Type 36, or Type 37 collar or lapped pipe end. The EN 1092-1 Type 04 loose plate flange shall always be used with the Type 34 weld-neck collar which has a tapered neck. As illustrated in Figure-2 (items 6 & 6′), the “collar” or “lapped pipe end” shall be furnished in straight pipe length with one end “lapped” or “flared” at right angles to the pipe axis. The EN 1092-1 Type 02 loose plate flange slips over the end of the pipe and sits properly onto the back face of the lapped collar. The loose plate flange can rotate to align bolt holes conveniently and is easily dismantled. Two identical sets of such “Type 02 + collar” assembly are bolted together with a flat gasket in between. Tightening the bolts causes the gasket material to flow into the minor machining imperfections, resulting in a fluid-tight seal. The piping is attached to the lapped collar by a full penetration welding process – butt welding. The fluid flowing through the flanged joint is only in contact with the lapped collar. The Type 02 loose plate flange has no contact with the fluid functioning as a back ring to support the collar.

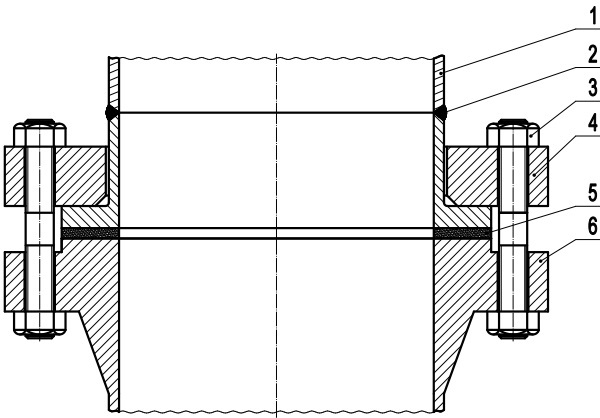

Figure-3: the “Type 02 + collar (Type 35)” bolted together with a RF flange. 1: pipe; 2: butt welds; 3: bolting; 4: Type 02 & Type 35 assembly; 5: gasket, 6: an integral flange with raised face.

Since the gasket-contacting surface of the lapped collar has dimensions of raised face, the “Type 02 + collar” assembly can be bolted together with a common flange with raised face in the same size as illustrated in Figure-3. The gaskets furnished to the joint may be non-metallic flat gaskets with or without inserts in accordance with EN 1514-1 or spiral wound gaskets in accordance with EN 1514-2. Provided a very smooth lapped surface (mirror-like finish) of the collar is produced by grinding, the metal-to-metal sealing can be achieved. Because it is expensive to grind the lapped surface to obtain fluid-tight joints, a gasket of some softer material is usually inserted between contact faces. EN 1092-1 Type 04 loose plate flange has exactly the same function as the Type 02 flange except that it is solely used with a Type 34 weld-neck collar which has a tapered neck.

EN 1092-1 Type 02 and Type 04 loose plate flanges with relative collar assemblies are primarily used on various piping systems that necessitate frequent dismantling for inspection or routine maintenance. It is also used in the installation of large diameter or hard-to-adjust piping configurations because of its quick bolt hole alignment. Especially in high alloy pipe work, a high alloy collar with a carbon steel loose plate flange is cheaper than a complete high alloy flange. These flanges are commonly used in mild service, where loads applied by the pipe to the flange connection are small. The longitudinal stresses in the piping resulting from pressure, weight, and thermal expansion shall be carefully calculated. Type 02 flanges are available in PN designations from PN 2.5 to PN 40, while Type 04 flanges are available in PN designations from PN 10 to PN 40.

EN 1092-1 Type 02 & Type 04 loose plate flanges are primarily made from a series of carbon steel or low alloy steel material grades such as P250GH, P245GH, S235JR, A105, P280GH, 16Mo3, P235GH, P265GH, P355NH, P355QH, etc. They can be made by a forging process or machined from bars or plates. They may also be made by a combined bending and electric welding process.

| DN | D mm | K mm | B mm | E mm |

|---|---|---|---|---|

| 10 | 75 | 50 | 21 | 3 |

| 15 | 80 | 55 | 25 | 3 |

| 20 | 90 | 65 | 31 | 4 |

| 25 | 100 | 75 | 38 | 4 |

| 32 | 120 | 90 | 46 | 5 |

| 40 | 130 | 100 | 53 | 5 |

| 50 | 140 | 110 | 65 | 5 |

| 65 | 160 | 130 | 81 | 6 |

| 80 | 190 | 150 | 94 | 6 |

| 100 | 210 | 170 | 120 | 6 |

| 125 | 240 | 200 | 145 | 6 |

| 150 | 265 | 225 | 174 | 6 |

| 200 | 320 | 280 | 226 | 6 |

| 250 | 375 | 335 | 281 | 8 |

| 300 | 440 | 395 | 333 | 8 |

| 350 | 490 | 445 | 365 | 8 |

| 400 | 540 | 495 | 416 | 8 |

| 450 | 595 | 550 | 467 | 8 |

| 500 | 645 | 600 | 519 | 8 |

| 600 | 755 | 705 | 622 | 8 |

| 700 | 860 | 810 | 721 | 4 |

| 800 | 975 | 920 | 824 | 4 |

| 900 | 1075 | 1020 | 926 | 4 |

| 1000 | 1175 | 1120 | 1028 | 4 |

| 1200 | 1375 | 1320 | 1234 | 5 |

| DN | C mm | n | d mm |

|---|---|---|---|

| 10 | 12 | 4 | 11 |

| 15 | 12 | 4 | 11 |

| 20 | 14 | 4 | 11 |

| 25 | 14 | 4 | 11 |

| 32 | 16 | 4 | 14 |

| 40 | 16 | 4 | 14 |

| 50 | 16 | 4 | 14 |

| 65 | 16 | 4 | 14 |

| 80 | 18 | 4 | 18 |

| 100 | 18 | 4 | 18 |

| 125 | 20 | 8 | 18 |

| 150 | 20 | 8 | 18 |

| 200 | 22 | 8 | 18 |

| 250 | 24 | 12 | 18 |

| 300 | 24 | 12 | 22 |

| 350 | 26 | 12 | 22 |

| 400 | 28 | 16 | 22 |

| 450 | 30 | 16 | 22 |

| 500 | 30 | 20 | 22 |

| 600 | 32 | 20 | 26 |

| 700 | 40 | 24 | 26 |

| 800 | 44 | 24 | 30 |

| 900 | 48 | 24 | 30 |

| 1000 | 52 | 28 | 30 |

| 1200 | 60 | 32 | 30 |

| DN | D mm | K mm | B mm | E mm |

|---|---|---|---|---|

| 10 | 75 | 50 | 21 | 3 |

| 15 | 80 | 55 | 25 | 3 |

| 20 | 90 | 65 | 31 | 4 |

| 25 | 100 | 75 | 38 | 4 |

| 32 | 120 | 90 | 46 | 5 |

| 40 | 130 | 100 | 53 | 5 |

| 50 | 140 | 110 | 65 | 5 |

| 65 | 160 | 130 | 81 | 6 |

| 80 | 190 | 150 | 94 | 6 |

| 100 | 210 | 170 | 120 | 6 |

| 125 | 240 | 200 | 145 | 6 |

| 150 | 265 | 225 | 174 | 6 |

| 200 | 320 | 280 | 226 | 6 |

| 250 | 375 | 335 | 281 | 8 |

| 300 | 440 | 395 | 333 | 8 |

| 350 | 490 | 445 | 365 | 8 |

| 400 | 540 | 495 | 416 | 8 |

| 450 | 595 | 550 | 467 | 8 |

| 500 | 645 | 600 | 519 | 8 |

| 600 | 755 | 705 | 622 | 8 |

| 700 | 860 | 810 | 721 | 4 |

| 800 | 975 | 920 | 824 | 4 |

| 900 | 1075 | 1020 | 926 | 4 |

| 1000 | 1175 | 1120 | 1028 | 4 |

| 1200 | 1405 | 1340 | 1234 | 5 |

| DN | C mm | n | d mm | Mass kg |

|---|---|---|---|---|

| 10 | 12 | 4 | 11 | 0.345 |

| 15 | 12 | 4 | 11 | 0.388 |

| 20 | 14 | 4 | 11 | 0.568 |

| 25 | 14 | 4 | 11 | 0.688 |

| 32 | 16 | 4 | 14 | 1.12 |

| 40 | 16 | 4 | 14 | 1.29 |

| 50 | 16 | 4 | 14 | 1.42 |

| 65 | 16 | 4 | 14 | 1.76 |

| 80 | 18 | 4 | 18 | 2.84 |

| 100 | 18 | 4 | 18 | 3.10 |

| 125 | 20 | 8 | 18 | 4.12 |

| 150 | 20 | 8 | 18 | 4.53 |

| 200 | 22 | 8 | 18 | 6.51 |

| 250 | 24 | 12 | 18 | 8.32 |

| 300 | 24 | 12 | 22 | 11.1 |

| 350 | 26 | 12 | 22 | 15.9 |

| 400 | 28 | 16 | 22 | 18.8 |

| 450 | 30 | 16 | 22 | 23.3 |

| 500 | 30 | 20 | 22 | 24.9 |

| 600 | 32 | 20 | 26 | 33.0 |

| 700 | 40 | 24 | 26 | 50.1 |

| 800 | 44 | 24 | 30 | 67.7 |

| 900 | 48 | 24 | 30 | 81.7 |

| 1000 | 52 | 28 | 30 | 95.5 |

| 1200 | 60 | 32 | 33 | 154 |

| DN | D mm | K mm | B mm | E mm |

|---|---|---|---|---|

| 10 | 90 | 60 | 21 | 3 |

| 15 | 95 | 65 | 25 | 3 |

| 20 | 105 | 75 | 31 | 4 |

| 25 | 115 | 85 | 38 | 4 |

| 32 | 140 | 100 | 47 | 5 |

| 40 | 150 | 110 | 53 | 5 |

| 50 | 165 | 125 | 65 | 5 |

| 65 | 185 | 145 | 81 | 6 |

| 80 | 200 | 160 | 94 | 6 |

| 100 | 220 | 180 | 120 | 6 |

| 125 | 250 | 210 | 145 | 6 |

| 150 | 285 | 240 | 174 | 6 |

| 200 | 340 | 295 | 226 | 6 |

| 250 | 395 | 350 | 281 | 8 |

| 300 | 445 | 400 | 333 | 8 |

| 350 | 505 | 460 | 365 | 8 |

| 400 | 565 | 515 | 416 | 8 |

| 450 | 615 | 565 | 467 | 8 |

| 500 | 670 | 620 | 519 | 8 |

| 600 | 780 | 725 | 622 | 8 |

| 700 | 895 | 840 | 721 | 8 |

| 800 | 1015 | 950 | 824 | 8 |

| 900 | 1115 | 1050 | 926 | 8 |

| 1000 | 1230 | 1160 | 1028 | 8 |

| 1200 | 1455 | 1380 | 1234 | 8 |

| DN | C mm | n | d mm | Mass kg |

|---|---|---|---|---|

| 10 | 14 | 4 | 14 | 0.591 |

| 15 | 14 | 4 | 14 | 0.654 |

| 20 | 16 | 4 | 14 | 0.909 |

| 25 | 16 | 4 | 14 | 1.08 |

| 32 | 18 | 4 | 18 | 1.77 |

| 40 | 18 | 4 | 18 | 2.02 |

| 50 | 20 | 4 | 18 | 2.52 |

| 65 | 20 | 8 | 18 | 3.05 |

| 80 | 20 | 8 | 18 | 3.48 |

| 100 | 22 | 8 | 18 | 4.20 |

| 125 | 22 | 8 | 18 | 5.21 |

| 150 | 24 | 8 | 22 | 6.89 |

| 200 | 24 | 8 | 22 | 8.87 |

| 250 | 26 | 12 | 22 | 11.2 |

| 300 | 26 | 12 | 22 | 12.8 |

| 350 | 30 | 16 | 22 | 20.9 |

| 400 | 32 | 16 | 26 | 26.4 |

| 450 | 36 | 20 | 26 | 32.2 |

| 500 | 38 | 20 | 26 | 38.5 |

| 600 | 42 | 20 | 30 | 52.2 |

| 700 | 50 | 24 | 30 | 79.4 |

| 800 | 56 | 24 | 33 | 112 |

| 900 | 62 | 28 | 33 | 135 |

| 1000 | 70 | 28 | 36 | 180 |

| 1200 | 83 | 32 | 39 | 278 |

| DN | D mm | K mm | B mm | E mm |

|---|---|---|---|---|

| 10 | 90 | 60 | 21 | 3 |

| 15 | 95 | 65 | 25 | 3 |

| 20 | 105 | 75 | 31 | 4 |

| 25 | 115 | 85 | 38 | 4 |

| 32 | 140 | 100 | 47 | 5 |

| 40 | 150 | 110 | 53 | 5 |

| 50 | 165 | 125 | 65 | 5 |

| 65 | 185 | 145 | 81 | 6 |

| 80 | 200 | 160 | 94 | 6 |

| 100 | 220 | 180 | 120 | 6 |

| 125 | 250 | 210 | 145 | 6 |

| 150 | 285 | 240 | 174 | 6 |

| 200 | 340 | 295 | 226 | 6 |

| 250 | 405 | 355 | 281 | 8 |

| 300 | 460 | 410 | 333 | 8 |

| 350 | 520 | 470 | 365 | 8 |

| 400 | 580 | 525 | 416 | 8 |

| 450 | 640 | 585 | 467 | 8 |

| 500 | 715 | 650 | 519 | 8 |

| 600 | 840 | 770 | 622 | 8 |

| 700 | 910 | 840 | 721 | 8 |

| 800 | 1025 | 950 | 824 | 8 |

| 900 | 1125 | 1050 | 926 | 8 |

| 1000 | 1255 | 1170 | 1030 | 8 |

| DN | C mm | n | d mm | Mass kg |

|---|---|---|---|---|

| 10 | 14 | 4 | 14 | 0.591 |

| 15 | 14 | 4 | 14 | 0.654 |

| 20 | 16 | 4 | 14 | 0.909 |

| 25 | 16 | 4 | 14 | 1.08 |

| 32 | 18 | 4 | 18 | 1.77 |

| 40 | 18 | 4 | 18 | 2.02 |

| 50 | 20 | 4 | 18 | 2.52 |

| 65 | 20 | 8 | 18 | 3.05 |

| 80 | 20 | 8 | 18 | 3.48 |

| 100 | 22 | 8 | 18 | 4.20 |

| 125 | 22 | 8 | 18 | 5.21 |

| 150 | 24 | 8 | 22 | 6.89 |

| 200 | 26 | 12 | 22 | 9.31 |

| 250 | 29 | 12 | 26 | 13.5 |

| 300 | 32 | 12 | 26 | 18.0 |

| 350 | 35 | 16 | 26 | 27.0 |

| 400 | 38 | 16 | 30 | 34.6 |

| 450 | 42 | 20 | 30 | 44.6 |

| 500 | 46 | 20 | 33 | 62.0 |

| 600 | 55 | 20 | 36 | 98.8 |

| 700 | 63 | 24 | 36 | 107 |

| 800 | 74 | 24 | 39 | 152 |

| 900 | 82 | 28 | 39 | 184 |

| 1000 | 90 | 28 | 42 | 257 |

| DN | D mm | K mm | B mm | E mm |

|---|---|---|---|---|

| 10 | 90 | 60 | 21 | 3 |

| 15 | 95 | 65 | 25 | 3 |

| 20 | 105 | 75 | 31 | 4 |

| 25 | 115 | 85 | 38 | 4 |

| 32 | 140 | 100 | 47 | 5 |

| 40 | 150 | 110 | 53 | 5 |

| 50 | 165 | 125 | 65 | 5 |

| 65 | 185 | 145 | 81 | 6 |

| 80 | 200 | 160 | 94 | 6 |

| 100 | 235 | 190 | 120 | 6 |

| 125 | 270 | 220 | 145 | 6 |

| 150 | 300 | 250 | 174 | 6 |

| 200 | 360 | 310 | 226 | 6 |

| 250 | 425 | 370 | 281 | 8 |

| 300 | 485 | 430 | 333 | 8 |

| 350 | 555 | 490 | 365 | 8 |

| 400 | 620 | 550 | 416 | 8 |

| 450 | 670 | 600 | 467 | 8 |

| 500 | 730 | 660 | 519 | 8 |

| 600 | 845 | 770 | 622 | 8 |

| 700 | 960 | 875 | 721 | 8 |

| 800 | 1085 | 990 | 824 | 8 |

| DN | C mm | n | d mm | Mass kg |

|---|---|---|---|---|

| 10 | 14 | 4 | 14 | 0.591 |

| 15 | 14 | 4 | 14 | 0.654 |

| 20 | 16 | 4 | 14 | 0.909 |

| 25 | 16 | 4 | 14 | 1.08 |

| 32 | 18 | 4 | 18 | 1.77 |

| 40 | 18 | 4 | 18 | 2.02 |

| 50 | 20 | 4 | 18 | 2.52 |

| 65 | 22 | 8 | 18 | 3.05 |

| 80 | 24 | 8 | 18 | 3.48 |

| 100 | 26 | 8 | 22 | 4.20 |

| 125 | 28 | 8 | 26 | 5.21 |

| 150 | 30 | 8 | 26 | 6.89 |

| 200 | 32 | 12 | 26 | 13.8 |

| 250 | 35 | 12 | 30 | 19.4 |

| 300 | 38 | 16 | 30 | 25.5 |

| 350 | 42 | 16 | 33 | 40.5 |

| 400 | 48 | 16 | 36 | 56.1 |

| 450 | 54 | 20 | 36 | 67.8 |

| 500 | 58 | 20 | 36 | 84.6 |

| 600 | 68 | 20 | 39 | 124 |

| 700 | 85 | 24 | 42 | 188 |

| 800 | 95 | 24 | 48 | 259 |

| DN | D mm | K mm | B mm | E mm |

|---|---|---|---|---|

| 10 | 90 | 60 | 21 | 3 |

| 15 | 95 | 65 | 25 | 3 |

| 20 | 105 | 75 | 31 | 4 |

| 25 | 115 | 85 | 38 | 4 |

| 32 | 140 | 100 | 47 | 5 |

| 40 | 150 | 110 | 53 | 5 |

| 50 | 165 | 125 | 65 | 5 |

| 65 | 185 | 145 | 81 | 6 |

| 80 | 200 | 160 | 94 | 6 |

| 100 | 235 | 190 | 120 | 6 |

| 125 | 270 | 220 | 145 | 6 |

| 150 | 300 | 250 | 174 | 6 |

| 200 | 375 | 320 | 226 | 6 |

| 250 | 450 | 385 | 281 | 8 |

| 300 | 515 | 450 | 333 | 8 |

| 350 | 580 | 510 | 365 | 8 |

| 400 | 660 | 585 | 416 | 8 |

| 450 | 685 | 610 | 467 | 8 |

| 500 | 755 | 670 | 519 | 8 |

| 600 | 890 | 795 | 622 | 8 |

| DN | C mm | n | d mm | Mass kg |

|---|---|---|---|---|

| 10 | 14 | 4 | 14 | 0.591 |

| 15 | 14 | 4 | 14 | 0.654 |

| 20 | 16 | 4 | 14 | 0.909 |

| 25 | 16 | 4 | 14 | 1.08 |

| 32 | 18 | 4 | 18 | 1.77 |

| 40 | 18 | 4 | 18 | 2.02 |

| 50 | 20 | 4 | 18 | 2.65 |

| 65 | 22 | 8 | 18 | 3.36 |

| 80 | 24 | 8 | 18 | 4.18 |

| 100 | 26 | 8 | 22 | 5.87 |

| 125 | 28 | 8 | 26 | 7.95 |

| 150 | 30 | 8 | 26 | 9.97 |

| 200 | 36 | 12 | 30 | 17.4 |

| 250 | 42 | 12 | 33 | 28.4 |

| 300 | 52 | 16 | 33 | 43.6 |

| 350 | 58 | 16 | 36 | 64.9 |

| 400 | 65 | 16 | 39 | 95.1 |

| 450 | - | 20 | 39 | - |

| 500 | - | 20 | 42 | - |

| 600 | - | 20 | 48 | - |

| DN | D mm | K mm | B' mm | E mm |

|---|---|---|---|---|

| 10 | 90 | 60 | 31 | 3 |

| 15 | 95 | 65 | 35 | 3 |

| 20 | 105 | 75 | 42 | 4 |

| 25 | 115 | 85 | 49 | 4 |

| 32 | 140 | 100 | 59 | 5 |

| 40 | 150 | 110 | 67 | 5 |

| 50 | 165 | 125 | 77 | 5 |

| 65 | 185 | 145 | 96 | 6 |

| 80 | 200 | 160 | 108 | 6 |

| 100 | 220 | 180 | 134 | 6 |

| 125 | 250 | 210 | 162 | 6 |

| 150 | 285 | 240 | 188 | 6 |

| 200 | 340 | 295 | 240 | 6 |

| 250 | 395 | 350 | 294 | 8 |

| 300 | 445 | 400 | 348 | 8 |

| 350 | 505 | 460 | 400 | 8 |

| 400 | 565 | 515 | 450 | 8 |

| 450 | 615 | 565 | 498 | 8 |

| 500 | 670 | 620 | 550 | 8 |

| 600 | 780 | 725 | 650 | 8 |

| DN | C mm | n | d mm | Mass kg |

|---|---|---|---|---|

| 10 | 14 | 4 | 14 | 0.549 |

| 15 | 14 | 4 | 14 | 0.606 |

| 20 | 16 | 4 | 14 | 0.836 |

| 25 | 16 | 4 | 14 | 0.990 |

| 32 | 18 | 4 | 18 | 1.65 |

| 40 | 18 | 4 | 18 | 1.85 |

| 50 | 20 | 4 | 18 | 2.34 |

| 65 | 20 | 8 | 18 | 2.76 |

| 80 | 20 | 8 | 18 | 3.17 |

| 100 | 22 | 8 | 18 | 3.78 |

| 125 | 22 | 8 | 18 | 4.57 |

| 150 | 24 | 8 | 22 | 6.22 |

| 200 | 24 | 8 | 22 | 7.90 |

| 250 | 26 | 12 | 22 | 9.99 |

| 300 | 26 | 12 | 22 | 11.1 |

| 350 | 30 | 16 | 22 | 14.7 |

| 400 | 32 | 16 | 26 | 20.5 |

| 450 | 36 | 20 | 26 | 25.5 |

| 500 | 38 | 20 | 26 | 30.7 |

| 600 | 42 | 20 | 30 | 43.0 |

| DN | D mm | K mm | B' mm | E mm |

|---|---|---|---|---|

| 10 | 90 | 60 | 31 | 3 |

| 15 | 95 | 65 | 35 | 3 |

| 20 | 105 | 75 | 42 | 4 |

| 25 | 115 | 85 | 49 | 4 |

| 32 | 140 | 100 | 59 | 5 |

| 40 | 150 | 110 | 67 | 5 |

| 50 | 165 | 125 | 77 | 5 |

| 65 | 180 | 145 | 96 | 6 |

| 80 | 200 | 160 | 108 | 6 |

| 100 | 220 | 180 | 134 | 6 |

| 125 | 250 | 210 | 162 | 6 |

| 150 | 285 | 240 | 188 | 6 |

| 200 | 340 | 295 | 240 | 6 |

| 250 | 405 | 355 | 294 | 8 |

| 300 | 460 | 410 | 348 | 8 |

| 350 | 520 | 470 | 400 | 8 |

| 400 | 580 | 525 | 454 | 8 |

| 450 | 640 | 585 | 500 | 8 |

| 500 | 715 | 650 | 556 | 8 |

| 600 | 840 | 770 | 660 | 8 |

| DN | C mm | n | d mm | Mass kg |

|---|---|---|---|---|

| 10 | 14 | 4 | 14 | 0.549 |

| 15 | 14 | 4 | 14 | 0.606 |

| 20 | 16 | 4 | 14 | 0.836 |

| 25 | 16 | 4 | 14 | 0.990 |

| 32 | 18 | 4 | 18 | 1.65 |

| 40 | 18 | 4 | 18 | 1.85 |

| 50 | 20 | 4 | 18 | 2.34 |

| 65 | 20 | 8 | 18 | 2.76 |

| 80 | 20 | 8 | 18 | 3.17 |

| 100 | 22 | 8 | 18 | 3.78 |

| 125 | 22 | 8 | 18 | 4.57 |

| 150 | 24 | 8 | 22 | 6.22 |

| 200 | 26 | 12 | 22 | 8.37 |

| 250 | 29 | 12 | 26 | 12.4 |

| 300 | 32 | 12 | 26 | 16.3 |

| 350 | 35 | 16 | 26 | 21.5 |

| 400 | 38 | 16 | 30 | 27.1 |

| 450 | 42 | 20 | 30 | 36.7 |

| 500 | 46 | 20 | 33 | 51.1 |

| 600 | 55 | 20 | 36 | 78.3 |

| DN | D mm | K mm | B' mm | E mm |

|---|---|---|---|---|

| 10 | 90 | 60 | 31 | 3 |

| 15 | 95 | 65 | 35 | 3 |

| 20 | 105 | 75 | 42 | 4 |

| 25 | 115 | 85 | 49 | 4 |

| 32 | 140 | 100 | 59 | 5 |

| 40 | 150 | 110 | 67 | 5 |

| 50 | 165 | 125 | 77 | 5 |

| 65 | 185 | 145 | 96 | 6 |

| 80 | 200 | 160 | 114 | 6 |

| 100 | 235 | 190 | 138 | 6 |

| 125 | 270 | 220 | 166 | 6 |

| 150 | 300 | 250 | 194 | 6 |

| 200 | 360 | 310 | 250 | 6 |

| 250 | 425 | 370 | 302 | 8 |

| 300 | 485 | 430 | 356 | 8 |

| 350 | 555 | 490 | 408 | 8 |

| 400 | 620 | 550 | 462 | 8 |

| 450 | 670 | 600 | 510 | 8 |

| 500 | 730 | 660 | 568 | 8 |

| 600 | 845 | 770 | 670 | 8 |

| DN | C mm | n | d mm | Mass kg |

|---|---|---|---|---|

| 10 | 14 | 4 | 14 | 0.549 |

| 15 | 14 | 4 | 14 | 0.606 |

| 20 | 16 | 4 | 14 | 0.836 |

| 25 | 16 | 4 | 14 | 0.990 |

| 32 | 18 | 4 | 18 | 1.65 |

| 40 | 18 | 4 | 18 | 1.85 |

| 50 | 20 | 4 | 18 | 2.34 |

| 65 | 22 | 8 | 18 | 2.76 |

| 80 | 24 | 8 | 18 | 3.17 |

| 100 | 26 | 8 | 22 | 3.78 |

| 125 | 28 | 8 | 26 | 4.57 |

| 150 | 30 | 8 | 26 | 6.22 |

| 200 | 32 | 12 | 26 | 11.6 |

| 250 | 35 | 12 | 30 | 17.0 |

| 300 | 38 | 16 | 30 | 22.0 |

| 350 | 42 | 16 | 33 | 32.1 |

| 400 | 48 | 16 | 36 | 44.5 |

| 450 | 54 | 20 | 36 | 54.2 |

| 500 | 58 | 20 | 36 | 65.9 |

| 600 | 58 | 20 | 39 | 98.4 |

| DN | D mm | K mm | B' mm | E mm |

|---|---|---|---|---|

| 10 | 90 | 60 | 31 | 3 |

| 15 | 95 | 65 | 35 | 3 |

| 20 | 105 | 75 | 42 | 4 |

| 25 | 115 | 85 | 49 | 4 |

| 32 | 140 | 100 | 59 | 5 |

| 40 | 150 | 110 | 67 | 5 |

| 50 | 165 | 125 | 77 | 5 |

| 65 | 185 | 145 | 96 | 6 |

| 80 | 200 | 160 | 114 | 6 |

| 100 | 235 | 190 | 138 | 6 |

| 125 | 270 | 220 | 166 | 6 |

| 150 | 300 | 250 | 194 | 6 |

| 200 | 360 | 310 | 250 | 6 |

| 250 | 425 | 370 | 302 | 8 |

| 300 | 485 | 430 | 356 | 8 |

| 350 | 555 | 490 | 408 | 8 |

| 400 | 620 | 550 | 462 | 8 |

| 450 | 670 | 600 | 510 | 8 |

| 500 | 730 | 660 | 568 | 8 |

| 600 | 845 | 770 | 670 | 8 |

| DN | C mm | n | d mm | Mass kg |

|---|---|---|---|---|

| 10 | 14 | 4 | 14 | 0.549 |

| 15 | 14 | 4 | 14 | 0.606 |

| 20 | 16 | 4 | 14 | 0.836 |

| 25 | 16 | 4 | 14 | 0.990 |

| 32 | 18 | 4 | 18 | 1.65 |

| 40 | 18 | 4 | 18 | 1.85 |

| 50 | 20 | 4 | 18 | 2.47 |

| 65 | 22 | 8 | 18 | 3.04 |

| 80 | 24 | 8 | 18 | 3.61 |

| 100 | 26 | 8 | 22 | 5.18 |

| 125 | 28 | 8 | 26 | 6.89 |

| 150 | 30 | 8 | 26 | 8.69 |

| 200 | 36 | 12 | 30 | 14.9 |

| 250 | 42 | 12 | 33 | 23.8 |

| 300 | 52 | 16 | 33 | 36.0 |

| 350 | 58 | 16 | 36 | 50.4 |

| 400 | 65 | 16 | 39 | 75.5 |

| 450 | 20 | 39 | ||

| 500 | 20 | 42 | ||

| 600 | 20 | 48 |

Tolerances for bore diameter B & B’: (1) for size ≤ DN 100, (0 mm, +0.5 mm); (2) for DN 100 < size ≤ DN 400, (0 mm, 1.0 mm); (3) for DN 400 < size ≤ DN 600, (0 mm, +1.5 mm); (4) for size > DN 600, (0 mm, +3.0 mm). Tolerances for outside diameter of flange D: (1) for size ≤ DN 150, (-2.0 mm, +2.0 mm); (2) for DN 150 < size ≤ DN 500, (-3.0 mm, +3.00 mm); (3) for DN 500 < size ≤ DN 1200, (-5.0 mm, +5.00 mm). Tolerances for flange thickness C: (1) for C ≤ 18 mm, (-1.3 mm, +1.0 mm); (2) for 18 mm < C ≤ 50 mm, (-1.5 mm, +1.5 mm); (3) for C > 50 mm, (-2.0 mm, +2.0 mm). Tolerances for bolt circle diameter K: (1) for bolt size M10 to M24, (-1.0 mm, +1.0 mm); (2) for bolt size M27 to M45, (-1.5 mm, +1.5 mm); (3) for bolt size > M45, (-2.0 mm, +2.0 mm). Tolerances for bolt hole diameter d: (1) for bolt size M10 to M24, (0 mm, +1.0 mm); (2) for bolt size M27 to M45, (0 mm, +2.5 mm); (3) for bolt size > M45, (0 mm, +4.0 mm).